The maintenance cost and lifespan of an Open Type Condensing Units depend on many factors, including the unit's design, quality, usage environment, frequency of use, and the timeliness and effectiveness of maintenance.

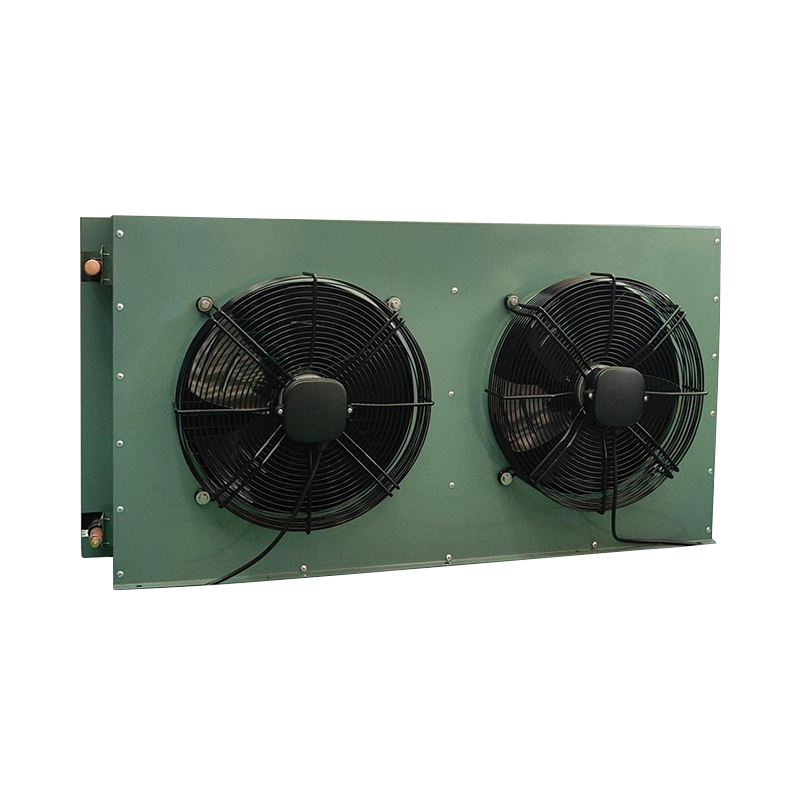

Preventive maintenance costs: In order to maintain the optimal performance of the unit and extend its service life, preventive maintenance is indispensable. This includes regular cleaning of the condenser to prevent the accumulation of dust and dirt that affects the cooling effect; replacement of filters to ensure cleanliness inside the system; and regular checking of refrigerant levels to ensure that the unit can continue to operate stably. Although these preventive maintenance measures require a certain cost investment, they can effectively avoid greater failures and downtime losses.

Emergency repair costs: Although preventive maintenance can reduce the frequency of emergency repairs, occasional breakdowns or damage can still occur. In this case, emergency repairs are necessary. The cost of emergency repairs is usually higher because it may involve replacing damaged parts, repairing damaged parts, and commissioning. In addition, if the unit is shut down in an emergency, it may also lead to production interruption and additional losses.

Maintenance personnel cost: Whether it is preventive maintenance or emergency repair, professional technicians are required to operate it. The training and wages of these technicians are also part of the maintenance costs. To ensure that the unit is properly maintained, users may need to hire or outsource a professional maintenance team.

Refrigerant cost: Refrigerant is necessary for the operation of the condensing unit, and its cost depends on the type of refrigerant, market price and usage. As environmental regulations tighten, some traditional refrigerants may face substitution, which may lead to rising costs. In addition, refrigerant leaks can also result in additional costs including leak detection, repair and recharging.

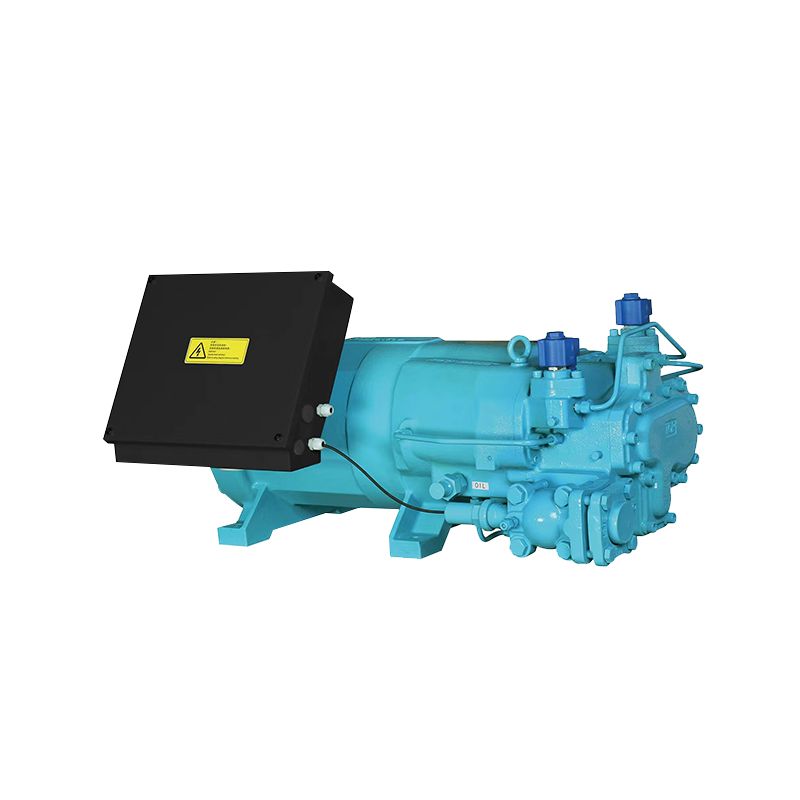

Design life: Open Type Condensing Unitss usually have a design life, which is the amount of time the manufacturer expects the unit to continue operating based on various factors during the design and production process (such as materials, manufacturing processes, testing, etc.). The length of the design life depends on the manufacturer's technical level and quality control capabilities.

Usage environment: The usage environment of the unit has a great impact on its lifespan. If the unit operates in a harsh environment, such as high temperature, high humidity, corrosive environment, etc., its components will be susceptible to corrosion and damage, thus shortening its life. On the contrary, a unit operating in a good environment may have a longer life.

Use and maintenance: The use and maintenance of the unit also directly affects its life. If the unit is frequently overloaded or operated under high temperature and high pressure for a long time, its components are prone to wear and aging. In addition, if regular maintenance is not performed or maintenance is improper, it may also lead to reduced performance and shortened life of the unit.

Component life: Each component in the unit has a different lifespan. Some wearing parts such as filters, seals, etc. may need to be replaced regularly, while some key components such as compressors, condensers, etc. may have a longer life. In order to extend the overall life of the unit, users need to pay attention to the life of each component and replace damaged components in a timely manner.

English

English Español

Español عربى

عربى русский

русский