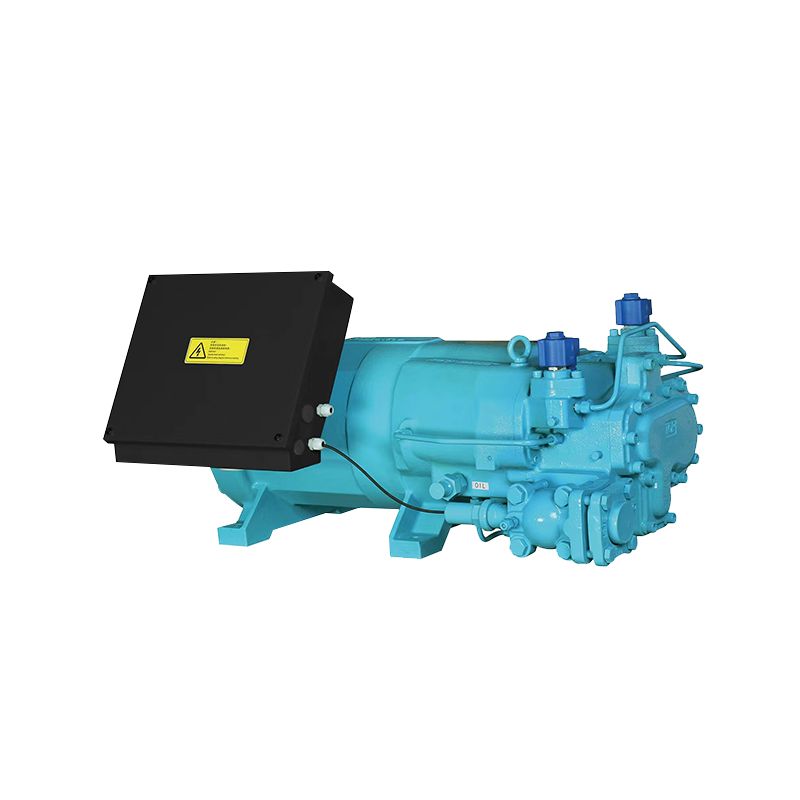

High-efficiency Copeland Scroll Compressor: Copeland Scroll compressor provides powerful power support for the entire system with its unique scroll design and exquisite high-precision manufacturing process. This scroll design cleverly uses the volume change between the rotating and fixed scroll walls to achieve gas compression, ensuring efficient energy conversion in each compression cycle. The scroll design of Copeland Scroll compressors provides higher compression efficiency than traditional compressors. During its operation, the gas is gradually compressed in the vortex cavity, reducing internal friction and leakage during the compression process, thereby significantly reducing energy loss. This design also makes the compressor run more smoothly, reducing mechanical vibration and noise, further improving the energy efficiency of the system.

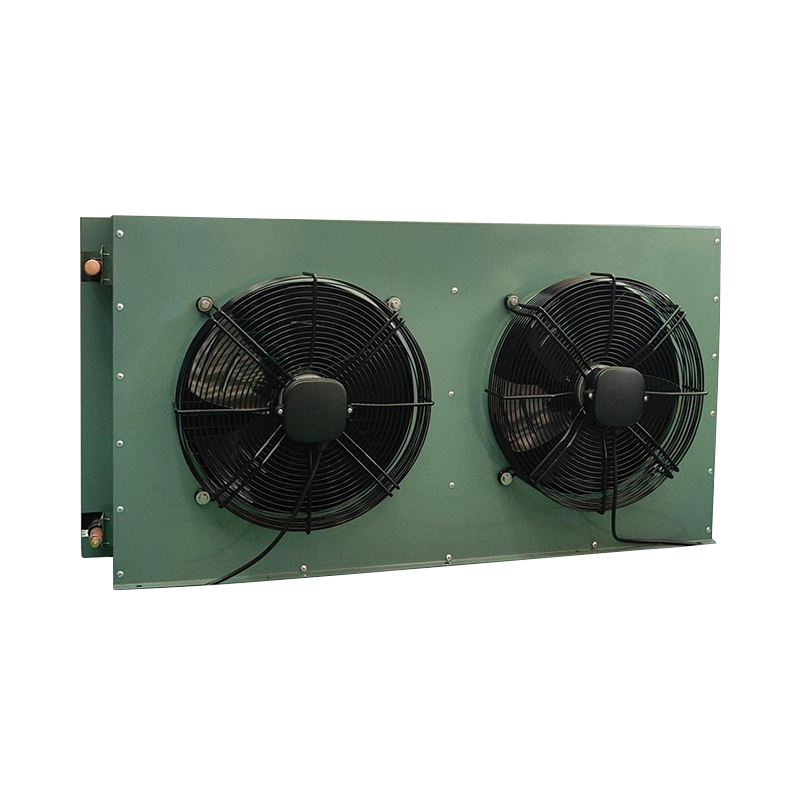

Optimized heat exchange performance: In Copeland Scroll compressor open condensing units, efficient heat exchange performance is the key to ensuring efficient operation of the system. The unit adopts a combined configuration of copper tubes and aluminum fins. This configuration not only makes full use of the high thermal conductivity of copper tubes and the lightweight characteristics of aluminum fins, but also achieves excellent heat exchange performance through optimized structural design. As the main medium for heat exchange, copper tubes' high thermal conductivity ensures that heat can be quickly transferred from the refrigerant to the fins. At the same time, copper pipes also have good corrosion resistance and can maintain stable performance in various complex working environments. Aluminum fins effectively dissipate heat to the surrounding environment by increasing the heat dissipation area. The design of the aluminum fins also takes into account the balance of air flow and heat transfer to achieve optimal heat dissipation. This optimized heat exchange performance allows the condenser to effectively dissipate the heat in the refrigerant at a lower temperature, thereby lowering the condensation temperature and improving refrigeration efficiency. At the same time, because the residence time of heat in the system is reduced, the energy consumption and operating costs of the system are also reduced.

Low-noise, high-efficiency axial flow fan motor: In industrial production and commercial applications, excessive noise will not only affect the comfort of the operator, but may also cause interference to the surrounding environment. In order to solve this problem, the fan motor adopts advanced low-noise technology, such as acoustic design, vibration-damping materials and optimized fan blades. These measures effectively reduce the noise level of the fan motor during operation, providing users with a quieter working environment. The fan motor can provide sufficient air volume with low energy consumption, which is crucial to improving the heat dissipation effect of the condenser and the overall energy efficiency of the unit. The fan motor adopts advanced motor technology and fluid mechanics design to ensure efficient and stable performance during operation. At the same time, it also has an intelligent speed adjustment function, which can automatically adjust the speed and air volume according to actual needs, further reducing energy consumption and costs.

Advanced control system: Copeland Scroll compressor open condensing units are usually equipped with advanced control systems, which is the key to efficient operation of the unit. This control system uses advanced sensors, controllers and algorithm technologies to monitor the operating status and parameters of the unit in real time. Through real-time monitoring, the control system can accurately grasp the operation of the unit, including key indicators such as temperature, pressure, and flow. Once these indicators appear abnormal or deviate from the set values, the control system will respond immediately and automatically adjust the operating parameters of the compressor or trigger corresponding protection measures. This kind of intelligent control can ensure that the unit operates in the best condition and avoid unnecessary energy waste and failure. By recording the operating data of the unit, users can understand the operation and performance of the unit, providing strong support for subsequent maintenance and optimization. At the same time, the control system can also be connected to the remote monitoring center to achieve remote monitoring and management, improving the maintainability and management efficiency of the unit.

In summary, the high-efficiency design and optimized heat transfer performance of Copeland Scroll compressors are the key to achieving efficient operation, energy conservation and environmental protection for Copeland Scroll compressor open condensing units. These advanced technologies and designs not only improve the energy efficiency of the system, but also bring users a more stable, reliable and economical operating experience.

English

English Español

Español عربى

عربى русский

русский