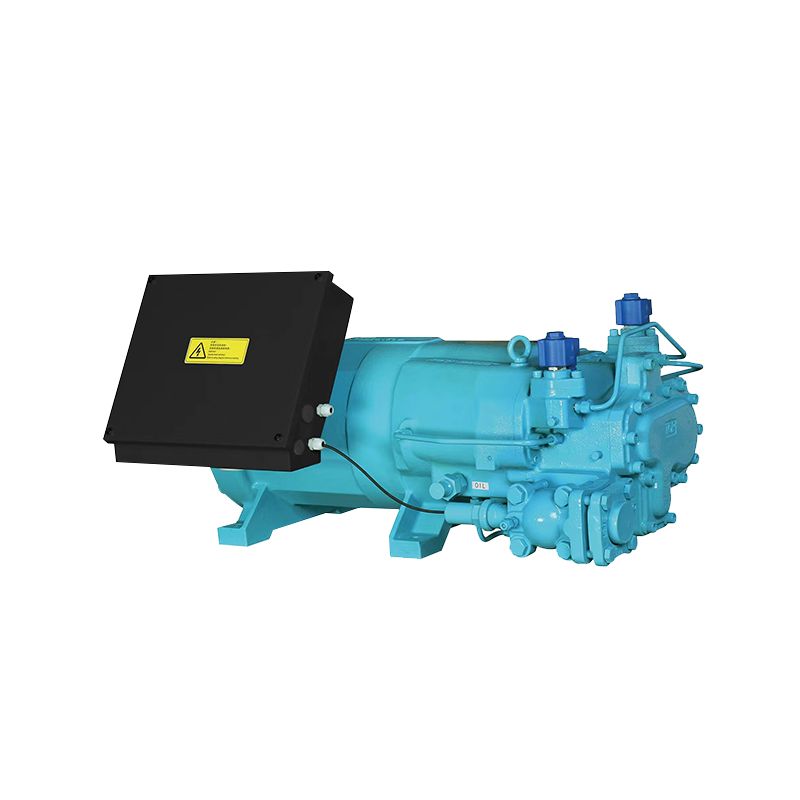

The efficient purification system of the automatic refrigerant management machine has several significant advantages, which not only improve the overall performance of the equipment, but also ensure the efficiency and safety of the refrigerant recovery and reuse process. The high-efficiency purification system can accurately separate the oil and moisture in the refrigerant, ensuring that the purity of the recovered refrigerant meets reuse standards. Through the separation of oil and water, the impact of impurities on the refrigeration system is avoided, and the quality and performance of the recovered refrigerant are improved.

The high-efficiency purification system of the automatic refrigerant management machine and the advanced filtration and separation technology integrated in the system ensure that even the smallest impurities are detected. In addition to being able to accurately capture and separate metal debris in the refrigerant, the system is also equipped with multi-stage filtration devices that effectively remove dust particles, Microfibers, organic residue and other invisible contaminants. This comprehensive impurity removal mechanism provides a solid guarantee for the purity of the refrigerant, thus avoiding problems such as system clogging, component wear, and efficiency decline that may be caused by the presence of impurities.

The deep processing capability of the high purification system uses innovative oil separation and replacement technology to target the deteriorated refrigeration oil that may be present in the original refrigerant. By precisely controlling parameters such as temperature, pressure and flow rate, the system can efficiently separate the deteriorated refrigeration oil from the refrigerant and inject new, high-quality refrigeration oil to restore the original performance of the refrigerant. This process not only extends the service life of the refrigerant, but also ensures that the performance of the newly circulated refrigerant meets or exceeds the original factory standards. In addition, the system also has the function of deep cleaning of refrigeration pipelines, using high-pressure water flow or special cleaning agents to completely remove dirt, sediments and microorganisms attached to the inner walls of the pipelines, laying a solid foundation for the stable operation of the refrigeration system.

In order to achieve convenient and efficient operation, the automatic refrigerant management machine adopts a highly integrated automatic control system. Users only need to touch the start button on the control panel, and the system can automatically complete a series of complex processes from impurity removal, oil-water separation to refrigeration oil replacement and pipeline cleaning. This design greatly simplifies the operating process, reduces the requirements for operators' professional skills, and also improves work efficiency and safety. The intelligent control module built into the system can monitor and adjust various operating parameters in real time to ensure that the purification process is always in the best state, thereby ensuring the consistency and stability of the purification effect.

With its efficient purification system, this automatic refrigerant management machine provides strong support for the recycling of refrigerants. By reducing the consumption of new refrigerant and the generation of waste, the system not only reduces production costs but also reduces pressure on the environment. More importantly, pure refrigerant can significantly reduce energy consumption and losses during recycling and improve the overall energy efficiency of the refrigeration system. This approach of reducing resource consumption and environmental pollution from the source coincides with the green and low-carbon concept currently advocated globally, and contributes positively to the sustainable development of the refrigeration industry.

To sum up, the high-efficiency purification system of the automatic refrigerant management machine has the advantages of efficient oil-water separation, powerful impurity removal, improved reuse standards, fully automated operation, energy saving and environmental protection. These advantages make this equipment have important application value and development prospects in the refrigeration industry.

English

English Español

Español عربى

عربى русский

русский