Magnetic bearing support technology: This green refrigeration compressor adopts advanced magnetic bearing support technology. Magnetic bearings use electromagnetic force to levitate and support rotating parts, resulting in lower friction and higher accuracy than traditional mechanical bearings. This contactless design reduces vibration and noise caused by mechanical friction, making the compressor run more smoothly and quietly.

Structural optimization and material selection: In order to reduce noise and vibration, the compressor pays special attention to structural optimization and material selection during the design and manufacturing process. Through precise mechanical analysis and simulation, designers optimized each component of the compressor to reduce vibration and noise. At the same time, high-strength, low-noise materials are used to manufacture compressor components, such as the use of lightweight alloys and composite materials, further reducing vibration and noise levels.

Sound-absorbing materials and sound-insulating devices: A variety of sound-absorbing materials and sound-insulating devices are used inside and outside the compressor to reduce noise. For example, install sound-absorbing foam or insulation panels inside the compressor casing to absorb the sound waves generated by vibration and reduce the transmission of noise. At the same time, a soundproof cover or soundproof board is installed outside the compressor to isolate the impact of noise on the surrounding environment. The combination of these sound-absorbing materials and sound insulation devices effectively reduces the noise level of the compressor.

Application of shock absorbers and shock absorbing pads: In order to reduce the impact of vibration generated by the compressor on the surrounding environment and equipment, devices such as shock absorbers and shock absorbing pads are used. A vibration absorber is a device that absorbs and reduces vibration energy and is usually installed at the bottom of the compressor or on the pipes connected to it. It converts vibration energy into heat energy or other forms of energy and dissipates it through the internal damping structure, thereby reducing the propagation of vibration. The shock-absorbing pad is a soft gasket used to isolate the compressor from direct contact with the ground or other structures to reduce vibration transmission to the surrounding environment.

Adjustment of operating mode: In addition to the above hardware measures, noise and vibration can also be reduced by adjusting the operating mode of the compressor. For example, use a smooth start and stop control system to avoid excessive shock and vibration when the compressor starts and stops. At the same time, adjust the speed and load of the compressor according to actual needs to avoid overload operation or frequent starts and stops to reduce vibration and noise.

To sum up, this green refrigeration compressor adopts various measures such as magnetic bearing support technology, structural optimization and material selection, sound-absorbing materials and sound insulation devices, application of shock absorbers and shock pads, and adjustment of operating modes. The operation effect of low noise and low vibration is achieved. These measures not only improve the performance and reliability of the compressor, but also provide users with a quieter and more comfortable environment.

Industry News

Home / News / Industry News / How does this green refrigeration compressor achieve low noise and low vibration?How does this green refrigeration compressor achieve low noise and low vibration?

Popular Recommendations

-

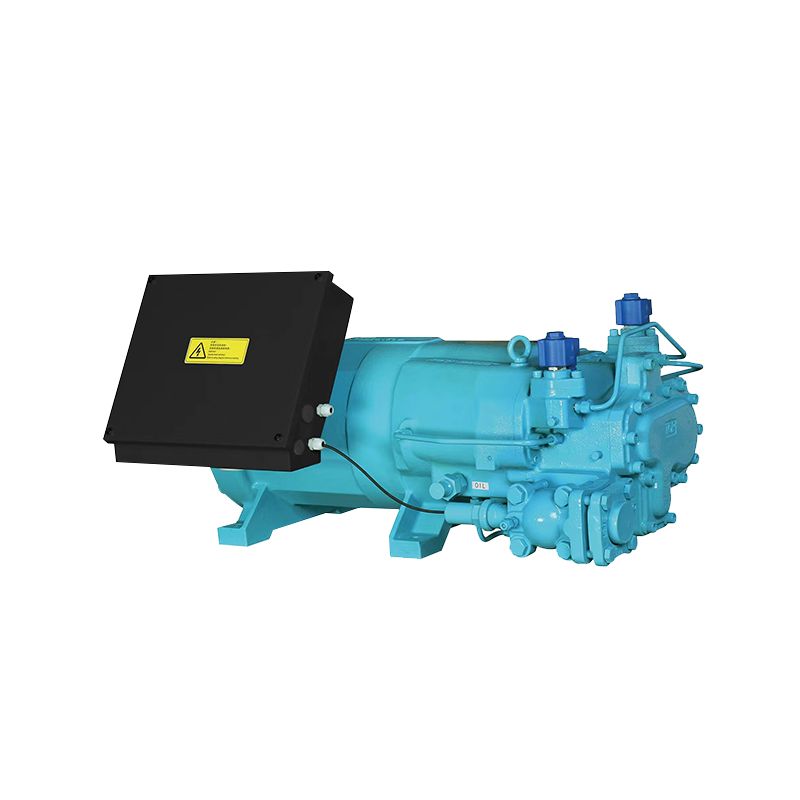

Briliant Six Cylinder Semi-Hermetic Piston Refrigeration Compressor

Suitable for a wide range of working conditions, including low (L), medium (M), and high (H) ba...

Briliant Four Cylinder Semi-Hermetic Piston Refrigeration Compressor

Various protection devices for the compressor, including overheat, overload, over-discharging t...

Briliant Low Temperature Bipolar Semi-Hermetic Piston Refrigeration Compressor

Various protection devices for the compressor, including overheat, overload, over-discharging t...

Briliant Semi-Hermetic Piston Refrigeration Compressor

Small volume, light weight, small vibration, low noise, high effciency and energy saving,environment...

Semi-Hermettc Screw Refrigeration Compressor

Small volume, light weight, small vibration, low noise, high effciency and energy saving,environment...

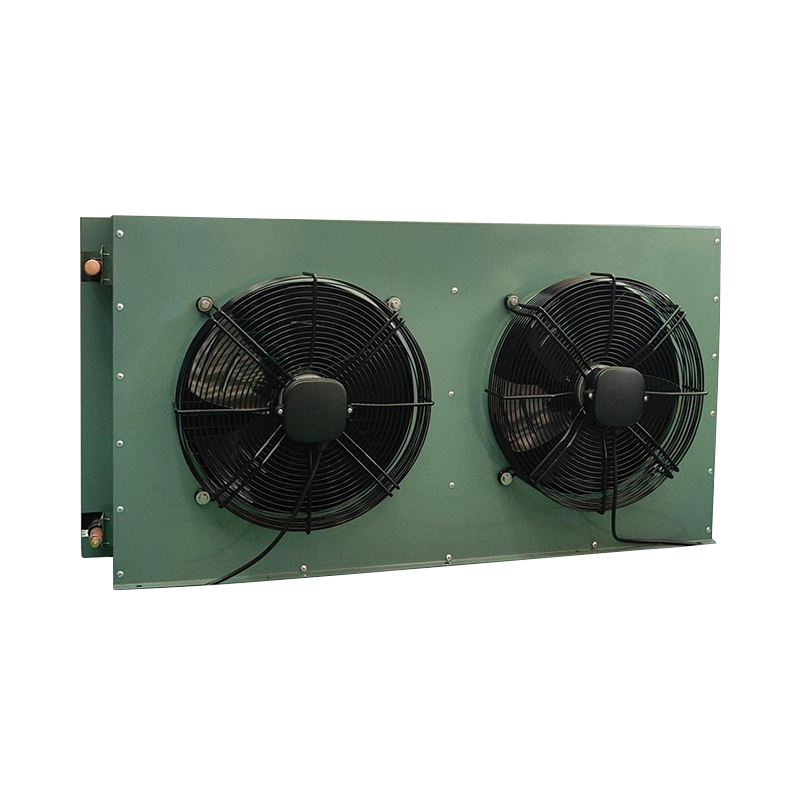

CDF Series Flat Type Condenser

• Conventional CDF type flat plate condenser suitable for applications.

• Adopt...

CDH Series H Type Condenser

• H type special model condenser• Adopt high efficiency heat exchange coil with alu...

CDV Series V Type Condenser

• V-shaped special model top air outlet condenser, suitable for medium and large condensing unit ...

DAIKIN B/D/G/Inverter/Multi-paralleled Type Scroll Compressor

- Provide high efficiency compressors by greater accurate machining. particular assemblingand...

Panasonic Scroll Compressor

- Liquid injection technology solves the problem of high discharge temperature at low evapora...

Hitachi Scroll Compressor For Residential Or Commercial Application

OUYUCOOL Type B Copeland/Danfoss Compresspor Condersing Unit

The box-type unit is an integral outdoor air-cooling unit with a compact structure and beautifu...Contact Our Experts

And Get A Free Consultation!Copyright? Ningbo Ouyu Import & Export Co., Ltd. All Rights Reserved Large Refrigeration Equipment Manufacturer

English

English Español

Español عربى

عربى русский

русский