The overall shell spray treatment of the CDH series H type condenser is a key process step, which is designed to significantly enhance its corrosion resistance and ensure that the condenser can operate stably for a long time in various harsh environments.

First, the plastic spray treatment effectively isolates the shell from the external environment by forming a uniform and dense coating on the surface of the condenser shell. It acts like a solid barrier, effectively isolating the condenser shell from the outside environment. During daily use, condensers often face challenges from various environmental factors, such as humid air, salty sea breeze, chemicals in industrial environments, etc. Once these corrosive substances come into contact with the condenser shell, they may cause damage to it. With the protection of this layer of coating, these corrosive substances are effectively blocked and cannot directly contact the surface of the shell, thus greatly reducing the possibility of corrosion. Secondly, the coating can also effectively prevent corrosion caused by oxidation. Oxidation is a common chemical reaction that causes metal surfaces to gradually lose their luster and even cause rust. However, the existence of this layer of coating is like putting a "protective coat" on the condenser shell to protect it from oxidation, thereby maintaining its original appearance and performance.

Secondly, the choice of spray paint plays a vital role in enhancing the corrosion resistance of CDH series H type condensers. Choosing high-quality spray paint is not only a high-quality protection for the condenser shell, but also an important guarantee for its long-term stable operation in various harsh environments. High-quality spray paint usually has a variety of superior properties. This kind of paint can withstand long-term exposure to wind, sun, rain, and snow, and will not degrade due to changes in the external climate. Whether it is the high temperature in the hot summer or the low temperature in the cold winter, the spray paint can maintain its original protective performance and ensure that the condenser shell is not damaged. In addition, high-quality plastic spray coatings offer excellent chemical resistance. In industrial production, condensers are often exposed to various chemical substances, such as acids, alkalis, salts, etc. Once these substances come into contact with the condenser shell, they may cause corrosion. However, high-quality spray paint can effectively resist the attack of these chemicals and keep the condenser shell intact.

In addition, the plastic spray treatment can also improve the surface hardness and smoothness of the condenser casing. First, through plastic spraying, a hard and strong coating can be formed on the surface of the condenser shell. This coating has high hardness and can effectively resist external physical damage and scratches. In an industrial production environment, the condenser shell often faces friction and collision with various objects, such as accidental scratches from tools, bumps during transportation, etc. However, with the protection of this hard coating, the case is able to effectively resist these damages and maintain its integrity and aesthetics. Secondly, the plastic spray treatment can also make the surface of the condenser shell smoother. The coating adheres closely to the surface of the case, eliminating potential bumps and roughness. This smooth surface not only makes the condenser look more beautiful, but more importantly, it effectively reduces the adhesion of dust and dirt. In industrial production, the accumulation of dust and dirt will not only affect the cooling effect of the condenser, but may also cause damage to internal components. The smooth surface is less likely to accumulate dust and dirt, allowing the condenser to stay clean, ensuring its normal operation.

Compared with traditional painting processes, plastic spray coatings have significant advantages in environmental protection. Plastic spray paint usually does not contain harmful substances, such as lead, mercury and other heavy metals, and does not release harmful gases, such as formaldehyde, benzene and other volatile organic compounds. During the plastic spraying process, no harm will be caused to operators and the environment. At the same time, during production and use, plastic spray coatings will not produce harmful waste or emissions, thus ensuring environmental friendliness. In addition, less waste is generated during the plastic spraying process. Compared with traditional painting processes, plastic spraying does not require the use of large amounts of solvents and thinners, thus reducing waste generation. At the same time, the utilization rate of plastic spray paint is also high, and almost zero waste can be achieved. These will help reduce the impact of industrial production on the environment and achieve sustainable development.

In summary, the overall plastic spray treatment of the shell of the CDH series H type condenser significantly enhances its corrosion resistance by forming an anti-corrosion coating, selecting high-quality paint, enhancing surface hardness and smoothness, and being environmentally friendly. . This treatment process ensures that the condenser can operate stably in various harsh environments, providing reliable guarantee for industrial production.

Industry News

Home / News / Industry News / How does the overall plastic spray treatment of the shell of the CDH series H type condenser enhance its corrosion resistance?How does the overall plastic spray treatment of the shell of the CDH series H type condenser enhance its corrosion resistance?

Popular Recommendations

-

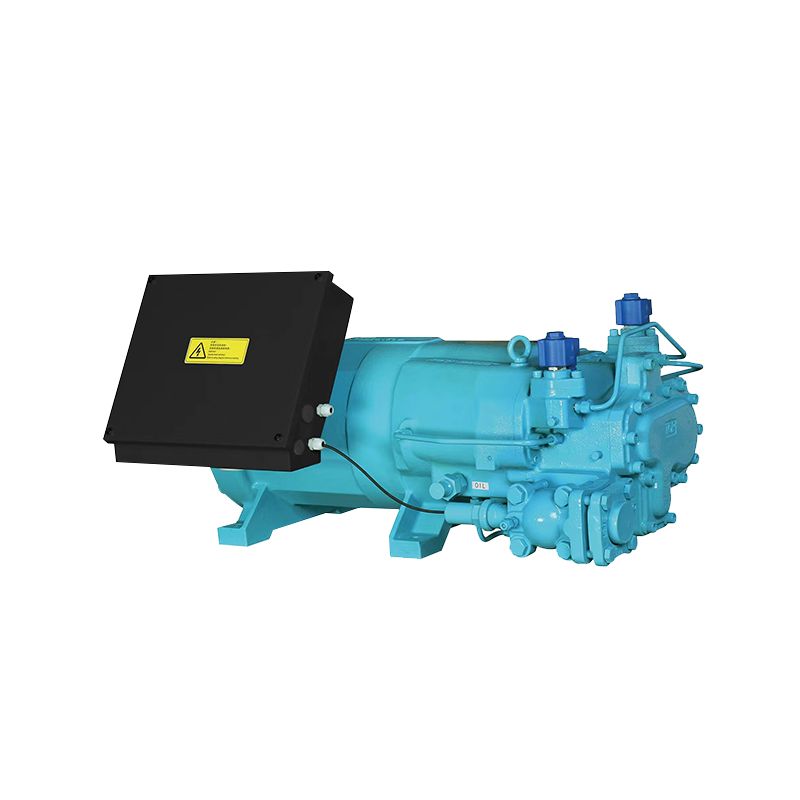

Briliant Six Cylinder Semi-Hermetic Piston Refrigeration Compressor

Suitable for a wide range of working conditions, including low (L), medium (M), and high (H) ba...

Briliant Four Cylinder Semi-Hermetic Piston Refrigeration Compressor

Various protection devices for the compressor, including overheat, overload, over-discharging t...

Briliant Low Temperature Bipolar Semi-Hermetic Piston Refrigeration Compressor

Various protection devices for the compressor, including overheat, overload, over-discharging t...

Briliant Semi-Hermetic Piston Refrigeration Compressor

Small volume, light weight, small vibration, low noise, high effciency and energy saving,environment...

Semi-Hermettc Screw Refrigeration Compressor

Small volume, light weight, small vibration, low noise, high effciency and energy saving,environment...

CDF Series Flat Type Condenser

• Conventional CDF type flat plate condenser suitable for applications.

• Adopt...

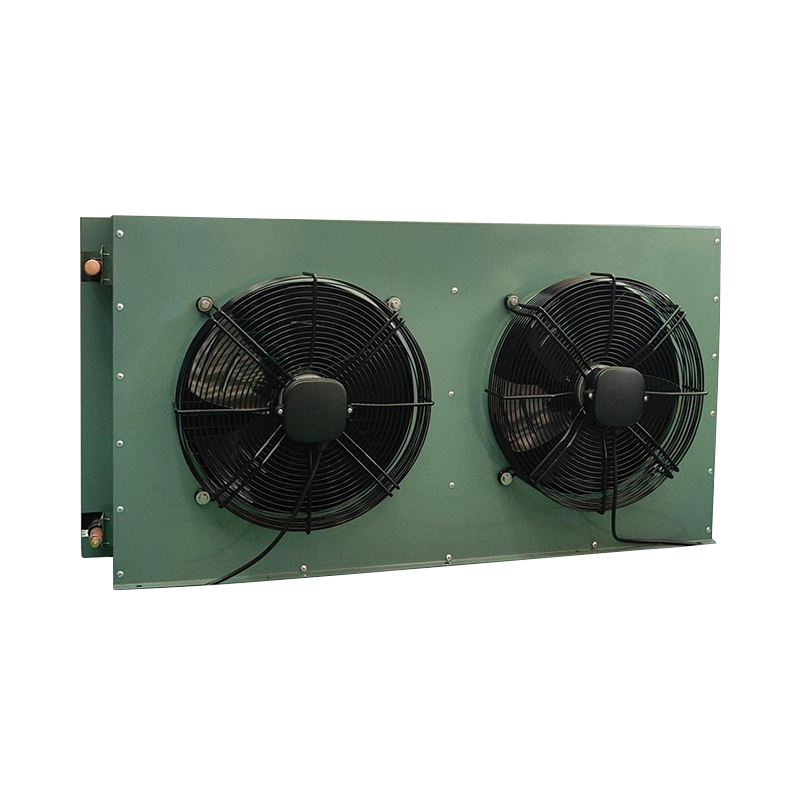

CDH Series H Type Condenser

• H type special model condenser• Adopt high efficiency heat exchange coil with alu...

CDV Series V Type Condenser

• V-shaped special model top air outlet condenser, suitable for medium and large condensing unit ...

DAIKIN B/D/G/Inverter/Multi-paralleled Type Scroll Compressor

- Provide high efficiency compressors by greater accurate machining. particular assemblingand...

Panasonic Scroll Compressor

- Liquid injection technology solves the problem of high discharge temperature at low evapora...

Hitachi Scroll Compressor For Residential Or Commercial Application

OUYUCOOL Type B Copeland/Danfoss Compresspor Condersing Unit

The box-type unit is an integral outdoor air-cooling unit with a compact structure and beautifu...Contact Our Experts

And Get A Free Consultation!Copyright? Ningbo Ouyu Import & Export Co., Ltd. All Rights Reserved Large Refrigeration Equipment Manufacturer

English

English Español

Español عربى

عربى русский

русский