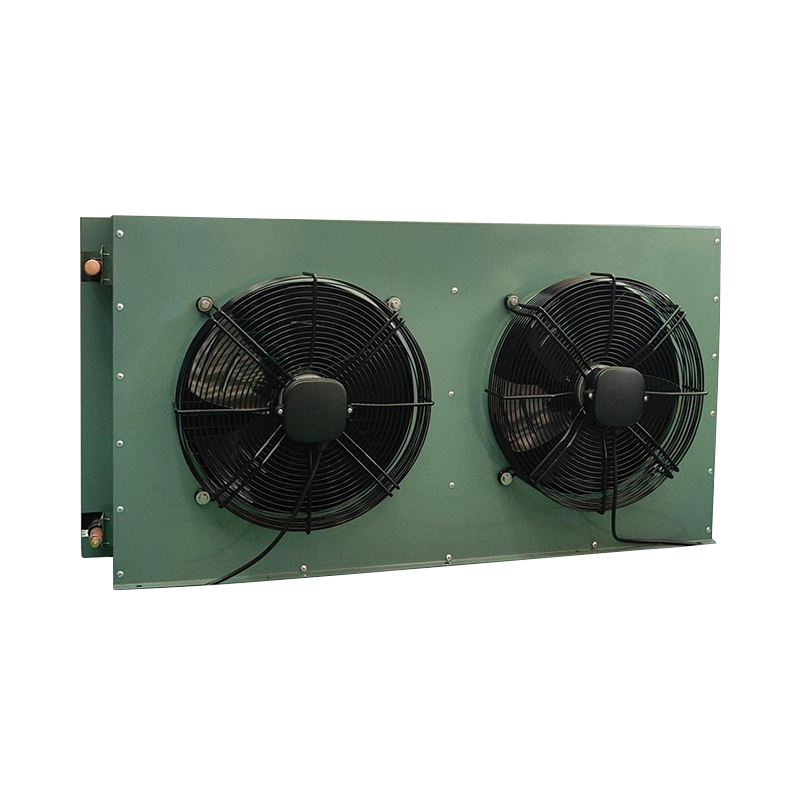

The high-efficiency aluminum fin heat exchange coils in V type condensers improve heat transfer efficiency in the following ways:

Increased heat transfer area: The aluminum fin design in the V type condenser is the core of its high-efficiency heat transfer ability. Fins are thin metal sheets attached to the outside of the copper tubes. They extend outward like branches, greatly increasing the total heat transfer area of the condenser. Compared with straight tubes without fins, the presence of fins increases the heat transfer area per unit volume exponentially. This design allows more heat to be exchanged in the same volume or area, so heat can be transferred from the fluid in the tube to the external environment more quickly.

Optimized fin structure: The shape and arrangement of the fins have an important impact on heat transfer efficiency. In the V type condenser, the fin punching design is an "L" row of extended fins, and the hole expansion process forms a unique structure. This structure not only increases the surface area of the fins, but also causes more disturbance when the air flows between the fins. This disturbance is crucial to improving heat transfer efficiency because it can destroy the thermal boundary layer formed on the fin surface. The thermal boundary layer is a layer of cooler fluid against the surface of the fins that impedes the transfer of heat from the hot fluid to the cold fluid. By increasing the fluid disturbance, this boundary layer can be broken up, making it easier for heat to transfer, thereby increasing the heat transfer coefficient.

Efficient heat transfer material: Aluminum is a lightweight, corrosion-resistant metal with high thermal conductivity, which makes it an ideal material for manufacturing fins. Aluminum fins can quickly disperse the heat transferred from the inside of the copper tube to the entire fin surface and then to the surrounding air. Due to the high thermal conductivity of aluminum, this heat transfer process is very fast and efficient.

Reduce thermal resistance: Thermal resistance is a factor that needs to be minimized during the heat exchange process. In the V type condenser, the close connection between the fins and the copper tubes is the key to reducing thermal resistance. This close connection ensures that heat can be smoothly transferred from the copper tube to the fins without being lost due to the gap between the contact surfaces. In addition, the connection between the fins and the copper tubes is usually made using welding or brazing techniques, which can provide a strong and low thermal resistance connection, further improving the heat exchange efficiency.

In summary, the high-efficiency aluminum fin heat exchange coil in the V type condenser significantly improves the heat transfer efficiency by increasing the heat transfer area, optimizing the fin structure, using high-efficiency heat conduction materials, and reducing thermal resistance. These design features work together to enable the V type condenser to exhibit superb heat transfer performance in various applications.

English

English Español

Español عربى

عربى русский

русский